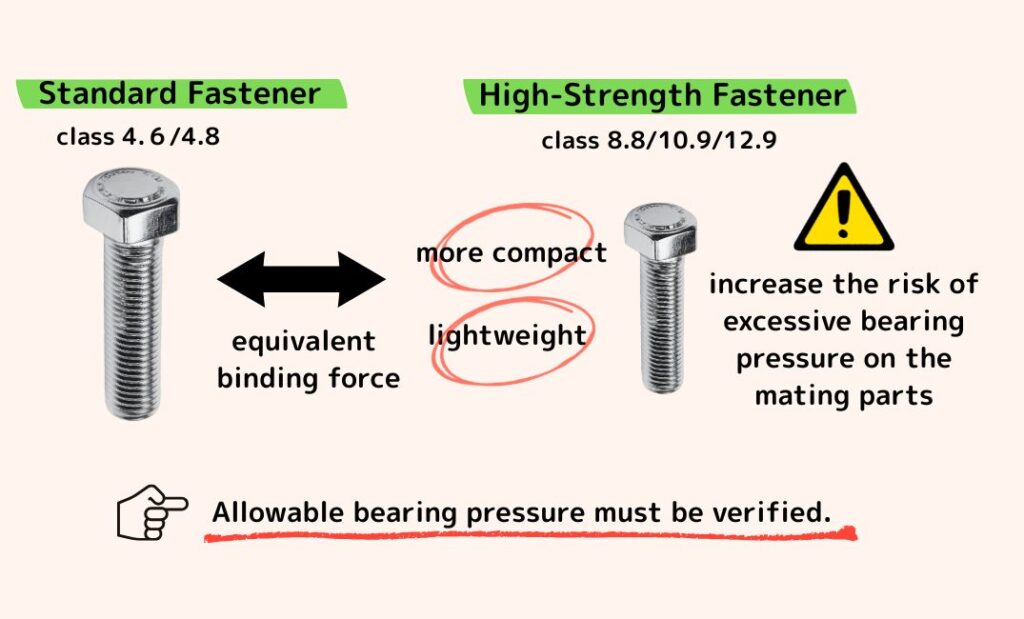

Many designers consider reducing bolt diameter in order to achieve size and weight reduction by using high-strength fasteners.

By upgrading from standard small screws or hex bolts with property classes such as 4.6 or 4.8 to high-strength bolts with classes 8.8, 10.9, or 12.9,

it becomes possible to replace an M6 bolt with a smaller M5 or M4 bolt, contributing to more compact and lightweight designs.

However, when making such changes, it is essential not to overlook the strength of the mating parts and the clamped components.

1. Consideration of Bearing Pressure on the Clamped Parts

When the bolt diameter is reduced, the bearing area under the bolt head also decreases, resulting in higher contact pressure per unit area.

If the applied bearing pressure exceeds the allowable bearing pressure of the clamped material, the following problems may occur:

- Local indentation (embedment) of the mating surface

- Loss of preload

- Early relaxation of the clamping force

This is particularly critical when the mating material is soft, such as aluminum or resin.

Even for ferrous materials, the allowable bearing pressure must be carefully evaluated.

2. Availability of Ultra High-Strength Fasteners

In Japan, ultra high-strength fasteners are available as standard stock items, such as:

- DIN 912 hex socket head cap screws with property class 14.9

- Austenitic stainless steel fasteners with property class A4-100

While these fasteners enable further downsizing, they significantly increase the risk of excessive bearing pressure on the mating parts.

3. Summary

Replacing standard fasteners with high-strength bolts is an effective approach to achieving size and weight reduction.

However, it is essential to carefully check the allowable bearing pressure of the mating and clamped materials when adopting high-strength fasteners.

【Writer】Tak Saima/CEO, Technical Sales