4th Generation/Tapping Screw for soft plastic!

Self-Tapping Screws for Plastic “Non-Sert”

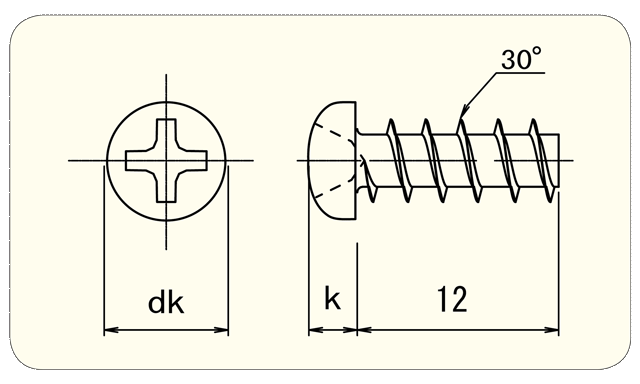

Pan Head Non-Sert

Steel 3Cr

Flat Head Non-Sert

Steel 3Cr

Pan Head Non-Sert

Steel Black Ni

Pan Head Non-Sert

Steel 3Cr

Pan Head Non-Sert

Stainless A2

Washer Head Non-Sert

Steel 3Cr

Binding Head Non-Sert

Steel 3Cr

Steel 3Cr

Steel 3Cr

Steel 3Cr Black

self tapping screw for

SANYO DENKI FAN

Steel 3Cr

self tapping screw for

SANYO DENKI FAN

Steel 3Cr BLACK

self tapping screw for

SANYO DENKI FAN

Steel 3Cr

self tapping screw for

SANYO DENKI FAN

Steel 3Cr BLACK

Made-to-order Non-Sert

Even if it is not listed in the catalog, it can be made to order.

e.g. 6-lob, Tamper-proof recesses, Truss heads, Round countersunk heads, Various platings, etc.

No Need Metal Insert

Possible to reduce the cost without metal insert.

No need countersinking process & expense for the metal insert.

non-sert will help you save total cost and time.

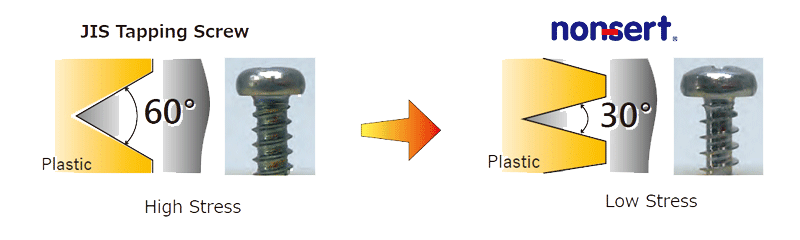

Sharp Thread Angle “30°”

Less stress and cracking on your plastic product.

Best for Repeat Use

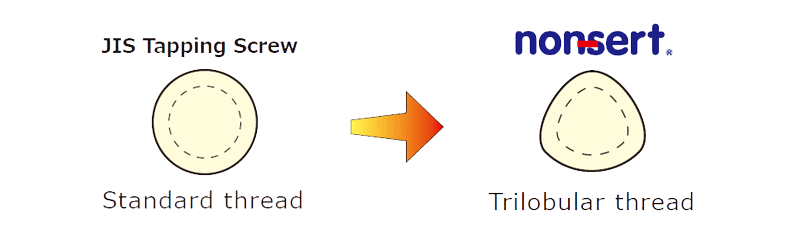

Trilobular thread = Low driving torque = less stress on the plastic.

non-sert can be used repeatedly on the same pilot hole.

Trilobular thread = Low driving torque = less stress on the plastic.

non-sert can be used repeatedly on the same pilot hole

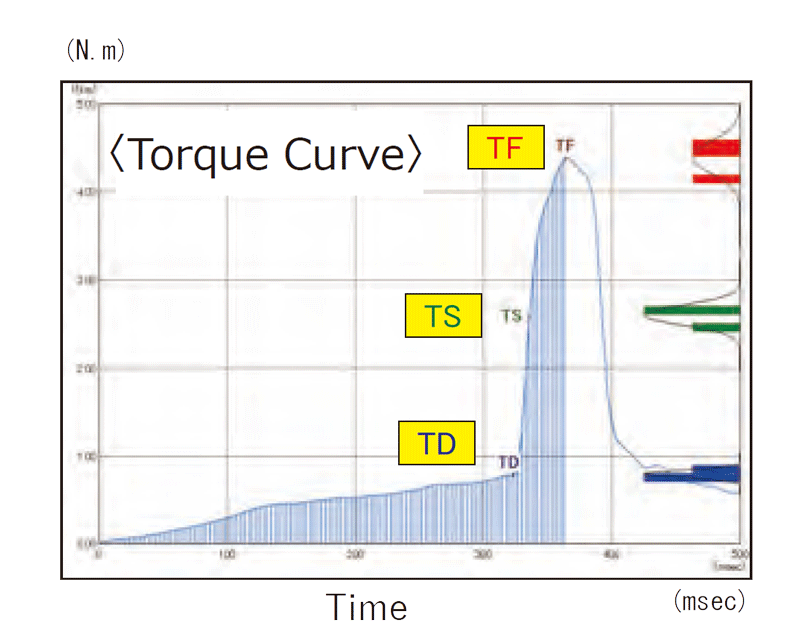

Low Driving Torque[TD] & High Failure Torque[TF]

Trilobular thread & sharp thread angle “30°” achieve low TD & high TF.

Pilot Hole Dia. & Torque of Setting

Torque Analyzer will…

- Find the best hole dia

- Find the best setting torque

Please feel to ask us if you’re annoyed with cracking & idling.

“Non-Sert” Hole Size (Self-Tapping Screws for Plastic)

Non-Sert is thread forming tapping screw to plastic material directly.

This thread structure is difficult to idling, and repeatable use.

*This table is as only reference.

*The best condition of hole diameter varies depending on the material and shape,

so We recommend using a PC Torque Analyzer to measure the optimum hole diameter.

| Material | Hole Size (d Size x) | |

|---|---|---|

| ABS | 0.80 | |

| PA6/6.6 | 0.75 | |

| PC | 0.85 | |

| PE | 0.70 – 0.75 | |

| PET | 0.75 | |

| PMMA | 0.85 | |

| POM | 0.75 | |

| PP | 0.70 | |

| PPO | 0.80 | |

| PS | 0.80 | |

| FRP | PET 30% | 0.80 |

| PA6 30% | 0.82 | |

| PA6.6 30% | 0.85 | |

| PC 30% | 0.80 | |

APPLICATION

- No Metal Insert Required. Cost Reduction.

- Easy to recycle without metal insert.

- Cracking is not expected

- Plastic Crack happen place

- Repeatable application

- Low torque driving, low stress for Self Tapping Screws Plastic

Gas Alarm

By adopting non-sert, it can be used as it is for plastic and it becomes possible to use it repeatedly for maintenance

Pump

Adopted non-sert for fastening of motor part and tube part housing

Plasma TV stand

By adopting non-sert, costs are reduced without requiring inserts

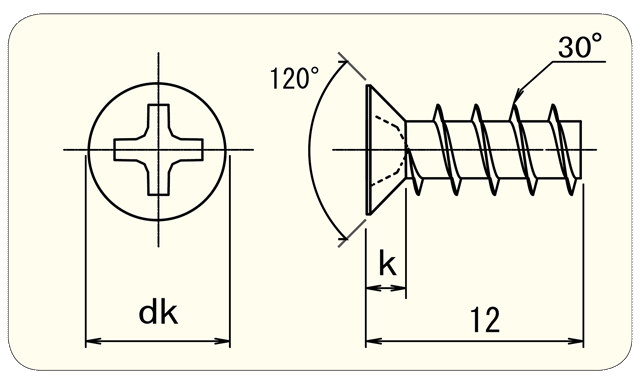

Non-Sert for SANYO DENKI FAN ”SAN ACE”

Special Self Tapping Screws for SAN ACE are developed with the SANYO DENKI CO., Ltd.

These are recommended by the SANYO DENKI CO., Ltd.

Small Pan Head type and 120° Flat Head type.

Technical date as below.

| Size | 4 | 4.8 | 5 |

|---|---|---|---|

| Head Dia(dk) | 5.5 | 7.0 | 7.0 |

| Head Height(k) | 2 | 2.6 | 2.6 |

| Length | 12 | 12 | 12 |

| Recess No. | 2 | 2 | 2 |

| Part No. | SY-NS010412P11(3Cr) | SY-NS014812P15(3Cr) | SY-NS010512P15(3Cr) |

| SY-NS010412P11BK(Black 3Cr) | SY-NS014812P15BK(Black 3Cr) | SY-NS010512P15BK(Black 3Cr) |

| Size | 4 | 4.8 | 5 |

|---|---|---|---|

| Head Dia(dk) | 6.2 | 6.8 | 6.8 |

| Head Height(k) | MAX1.1 | MAX1.2 | MAX1.2 |

| Length | 12 | 12 | 12 |

| Recess No. | 2 | 2 | 2 |

| Part No. | SY-NS020412P11(3Cr) | SY-NS024812P15(3Cr) | SY-NS020512P15(3Cr) |

| SY-NS020412P11BK(Black 3Cr) | SY-NS024812P15BK(Black 3Cr) | SY-NS020512P15BK(Black 3Cr) |

4th Generation Thread Forming

Plastic and Engineering Plastic counterpart is much weaker than Steel Screw.

Therefore, to prevent the plastic breaking or cracking, SAIMA is strongly recommend to use “specialized screw for plastic”.

1st Generation: JIS B 1122 type 2 (Self Tapping Screws for Plastic)

Suitable for thin plate and plastic fastening as stated in JIS B1122 appendix.

Widely distributed as a standard screw. Average Performance.

2nd Generation: B-type (Self Tapping Screws for Plastic)

Advanced form of JIS B 1122 Class 2, with trilobular thread, same thread angle (60 degree) and pitch.

Tightening Torque is lower than 1st generation according to torque analysis result.

Suitable for thin plate and plastic fastening.

3rd Generation: P-type (Self Tapping Screws for Plastic)

Double threaded with 45° thread angle, wider thread compared with B-type and trilobular thread.

Double started thread makes the fastening speed twice high, but loosens faster once the screw starts loosening.

This makes TF point and TD point higher, so we havet to pay attention F/D ratio.

This is not suitable for repeated application on the same pilot hole.

TD: Torque of Driving

Min. Torque for fatening

TF: Torque of Failure

Torque for breaking counter material. it includes idling and crack

TS: Torque of Setting

Best Torque of Setting

4th Generation: Non-Sert (Self Tapping Screws for Plastic)

Single threaded same as 1st and 2nd Generation with 30-degree thread angle, trilobular thread shape and large pitch. Lowest TD(Torque of Driving) in all generations. Low stress against the plastic part. TF(Torque of Failure) is lower than 3rd Generation, but mostly T/F ratio indicate higher, these results conclude that using Non-Sert is safe and best Self Tapping Screws for Self-Tapping Screws for Plastic fastening. In addition, that Best for repeat use on the same hole.