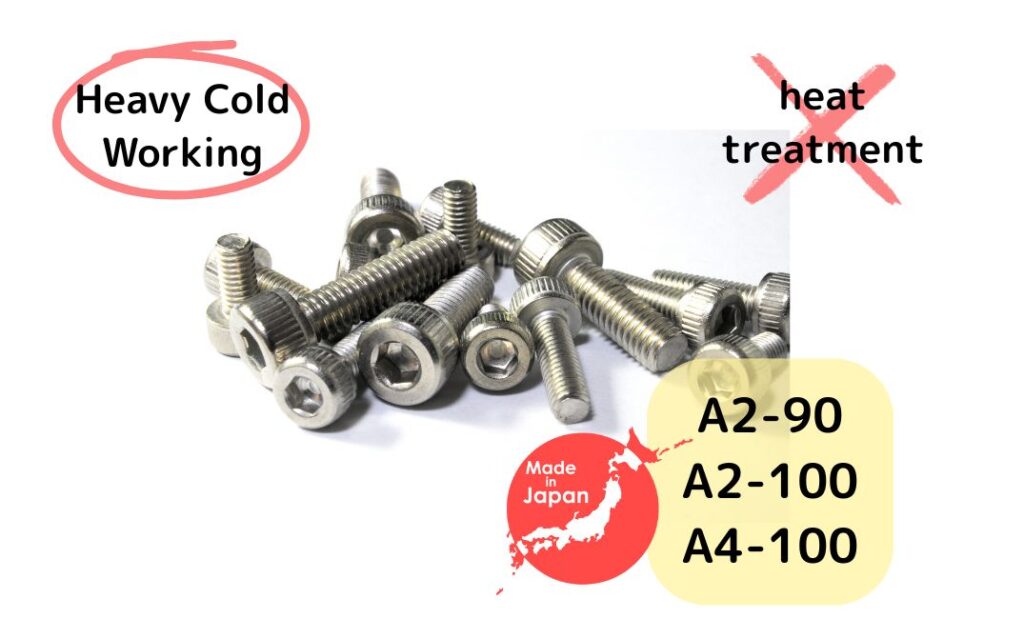

📌 Work Hardening of Austenitic Stainless Steel

Austenitic stainless steels such as A2 and A4 grades cannot be strengthened through heat treatment.

Therefore, cold working (cold forming) is used to induce work hardening, allowing the production of high-strength A2 and A4 fasteners.

In Japan, we manufacture high-strength DIN 912 socket head cap screws such as:

- A2-90

- A2-100

- A4-100

🛠️ Why High-Strength Stainless Screws Can Be Made in Japan

The production of high-strength stainless steel fasteners is made possible in Japan due to the availability of:

- Specialty material suppliers

- Precision wire drawing companies

- Header dies and tooling manufacturers

- Punch makers

All of these elements are readily accessible within Japan, supporting small to medium-scale precision production.

🔄 Shift from Mass Production to Small-Lot Specialization

Japan largely moved away from the mass production of low-cost bolts and nuts more than 30 years ago.

Instead, the domestic industry has evolved to support flexible small-lot procurement, including:

- Raw materials available from as little as 100 kg

- Plating and heat treatment services that accept small-lot processing (around 100 kg)

Although plating and heat treatment are not directly applicable to A2 and A4, this infrastructure still supports agile, low-volume, high-quality production.

🇯🇵 Try Japanese Screws

- A2-90

- A2-100

- A4-100

If you’re seeking high-strength stainless steel fasteners with reliable quality and tight tolerances,

why not try Japanese-made screws?

【Writer】Tak Saima/CEO, Technical Sales