Japanese Micro Screw Manufacturing Technology

At SAIMA Group, we manufacture screws ranging from M1 to M12, using a variety of materials including:

- Carbon steel

- Alloy steel

- Stainless steel (A2, A4)

- Aluminum (5000, 6000, 7000 series)

- Brass

- Copper

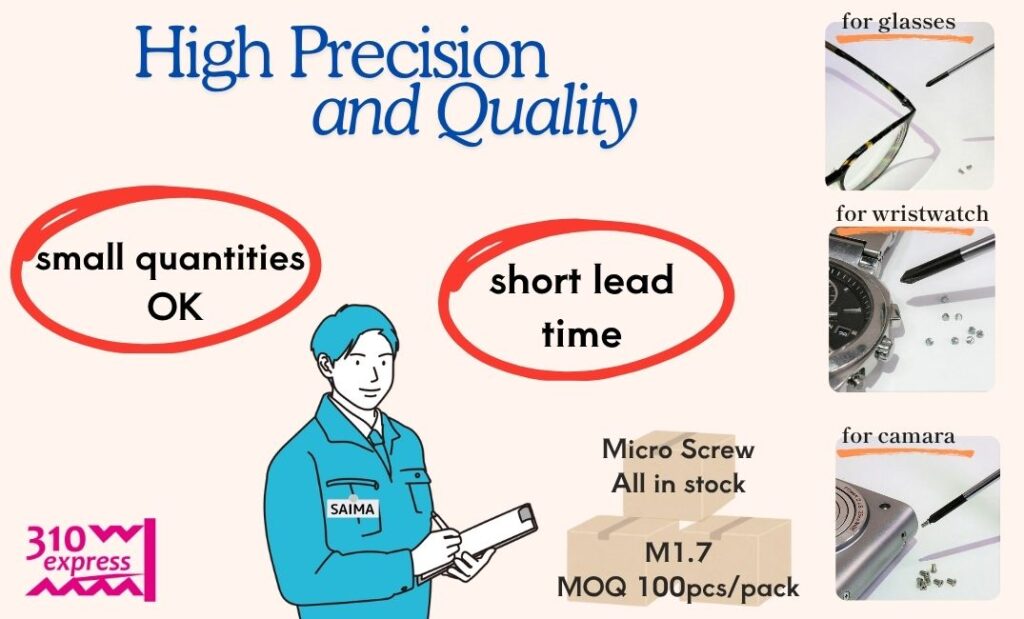

Our minimum production quantity is 30,000 pieces — considered a small lot by international standards. In fact, this level of low-volume production is rarely offered in other Asian manufacturing countries.

Production of screws smaller than M1 (e.g., 0.8mm) is also possible, including precision micro screws, pins, and connectors.

For sizes below M2, specialized production equipment is essential, including:

- Precision headers

- Rolling machines

- Cleaning equipment for oil removal

- High-quality drawn wire materials

- Electroplating systems

- Heat treatment facilities

- Precision packaging

- Screw gauges

- Recess (torque) gauges, e.g., cross-recess engagement gauges

- Image-based sorting machines

While some M4-level production equipment can technically handle miniature screws, we believe dedicated machinery is essential to achieve consistent high precision and quality.

We also maintain stock inventory, and can provide quotations for quantities below 30,000 pieces.

If you’ve faced challenges such as:

- Being declined due to “too small” quantities

- Unreasonably high minimum order requirements

- Excessively long lead times

…please feel free to consult with us. We are ready to support your needs with Japan’s specialized miniature screw manufacturing capability.

【Writer】Tak Saima/CEO, Technical Sales