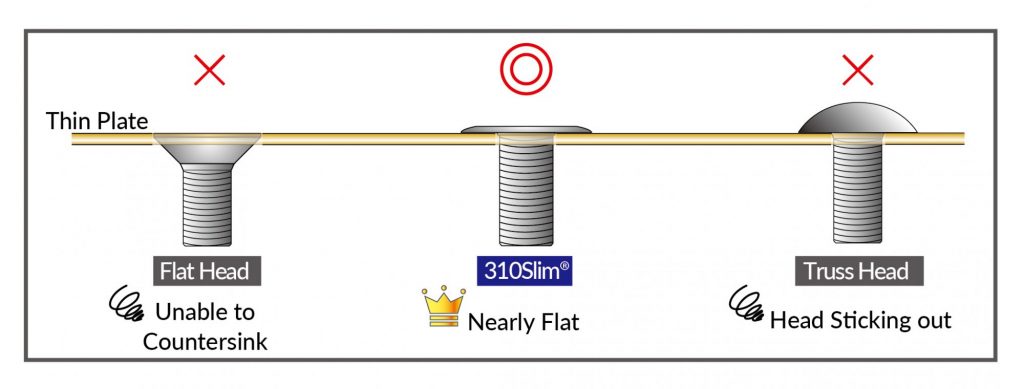

Thin Plates that Cannot be Used with Countersunk Screws can be Made Almost Flat.

Countersunk screws cannot be used on thin plates.

Thin plates cannot be zaglied for countersunk screws.

The 310Slim® does not have a protrusion like a pan head or truss head, making it ideal for thin plate fastening.

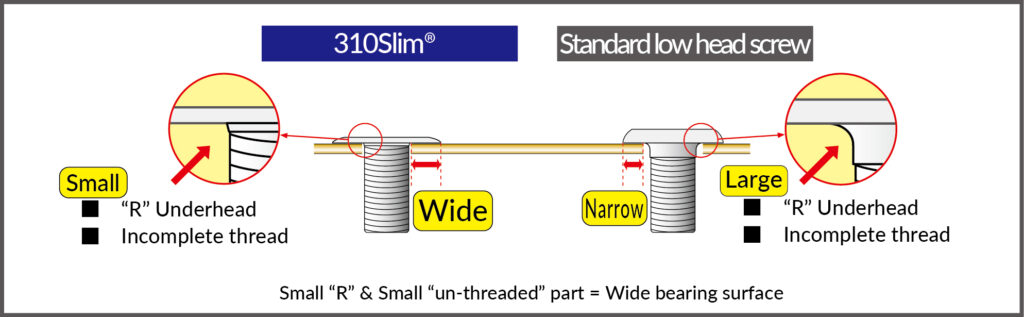

Compact Design Underhead “R” & “Un-threaded” Part

Small “R”

Small clearance hole = Wide bearing surface ⇒ Stable Fastening

Small “Un-threaded” part

Fully threaded under the head ⇒ Best for thin plate fastening

The small “R under the neck” and the “Incomplete threaded part” contribute to the miniaturization of the product.

The 310Slim® is designed to have a smaller radius and imperfect thread to make your product smaller and space-saving.